Description

SPECIFICATIONS

After-sales Service Provided: Engineers available to service machinery overseas

Application: Liquid Powder

Brand Name: NoEnName_Null

Capacity: 25L

Certification: CE

Color: Customized

Condition: New

DIY Supplies: Electrical

Evaporation Capacity(kg/h): 5-1000

Feature: High Efficiency Low Cost

Heating source: Electricity, gas, steam, etc.

Hign-concerned Chemical: None

Marketing Type: New Product 2020

Material: Stainless Steel

Model Number: GLT-SP-25

Origin: Mainland China

Voltage: Customizable

Warranty of core components: 1 Year

Weight: 1000kg

application: Chemicals Processing, Plastics Processing, Food Processing

brand name: Great

core components: Bearing, Gearbox, PLC

dimension(l*w*h): 4000*2700*4500mm

heating method: Gas ,Oil ,Electric ,Steam Heating

key selling points: High Productivity

machinery test report: Provided

material: SUS304

place of origin: Henan, China

power(w): 31kw

type: Spray Drying Equipment

video outgoing-inspection: Provided

voltage: 220v/380v

warranty: 1 Year

weight (kg): 500

Hello dear friend.The shipping cost on the item page may not match the actual, please contact me and leave your specific shipping address and city postcode and I will check the detailed shipping cost for you! Please contact me to communicate accurate pricing! If you need to enquire about other models, customised items and discounts, please contact me and I will be online 24 hours a day. There are other ways to contact me in order to get back to you first: Whatsapp:+86 13627367167 Email 3140006550@qq.com

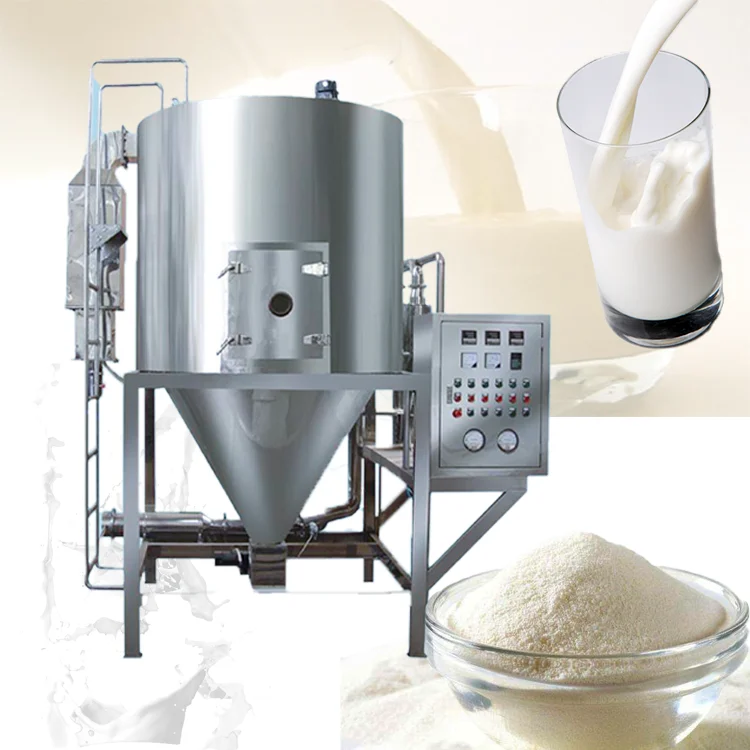

milk powder spray dryer good price spray dryer

Industrial spray dryer

Description of spray dryer

Click Now for Catalogs & Factory Price!

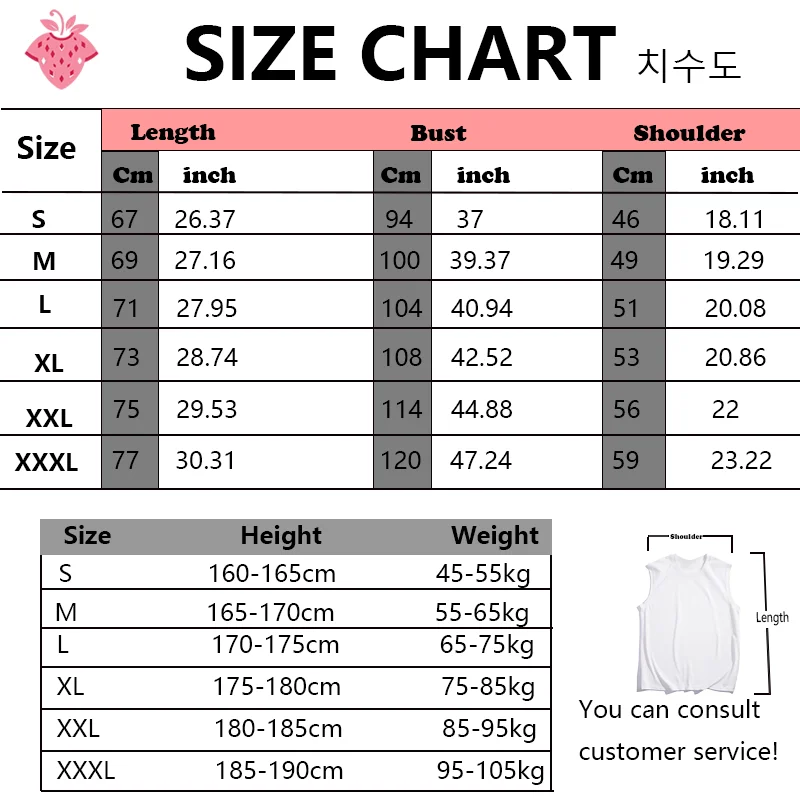

| Model | Size | Tower body | Centrifugal spray atomizer | Materail | Heating source |

| GLT-SP-5 | 1600×1100×1750mm | Φ1000mm | Φ50 mm | stainless steel | Electric

Steam Gas Coal |

| GLT-SP-25 | 4000×2700×4500mm | Φ1750mm | Φ80 mm | ||

| GLT-SP-50 | 4500×2800×5500mm | Φ2300mm | Φ120mm | ||

| GLT-SP-100 | 5200×3500×6700mm | Φ2700mm | Φ150mm | ||

| GLT-SP-200 | 7500×6000×8000 | Φ3200mm | Φ150mm | ||

| GLT-SP-1000 | Customized | ||||

Application of spray dryer

Chemical industry

Sodium fluoride (pqtassium), alkaline dyestuff and pigment, dyestuff intermediate, compound fertilizer, formic silicic acid, catalyst, sulphuric acid agent, amino acid, white carbon and so on.

Plastics and resin

AB, ABS emulsion, uric acid resin, phenolic aldehyde resin, urea-formaldehyde resin, formaldehyde resin, polythene, poly chloroprene, etc.

Food industry

Fatty milk powder, protein, cocoa milk powder, substitute milk powder, egg white (yolk), food and plant, oats, chicken juice, coffee, instant sissoluble tea, seasoning meat, protein, soybean, peanut protein, hydrolysate and so forth.

Features of spray drye machine

Other modes of spray dryer

|

|

|

|

| Spray drying machine | Belt microwave dryer | Hot air circulation oven | Drum dryer for liquid |

| Click on the picture or text for more information | |||

Leave a Reply